Unlocking Innovation: How a china rapid prototyper Revolutionizes Metal Fabrication & Business Success

In the rapidly evolving landscape of modern manufacturing, businesses are continually seeking ways to accelerate product development, reduce costs, and improve overall quality. Among the innovative solutions transforming the industry, china rapid prototyper services stand out as a game-changing asset for companies in need of swift, precise, and cost-effective metal fabrication. This comprehensive guide explores how leveraging a top-tier china rapid prototyper can drive your business forward, enhance your manufacturing capabilities, and establish a competitive advantage in a global marketplace.

Understanding the Role of a China Rapid Prototyper in Modern Business

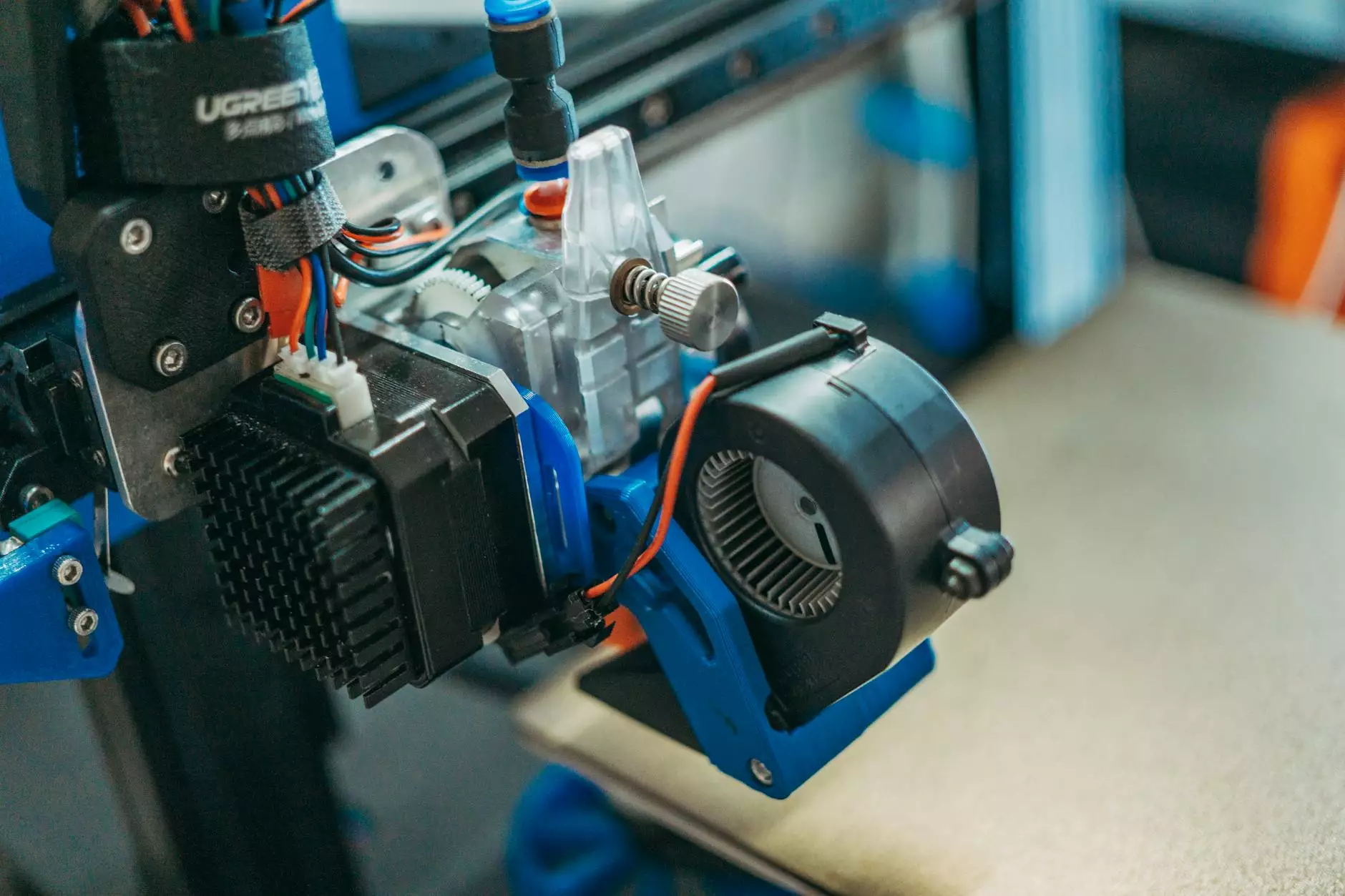

At its core, a china rapid prototyper refers to advanced manufacturing facilities in China specializing in rapid prototype development, particularly for complex metal parts. These facilities utilize state-of-the-art technological processes such as CNC machining, metal 3D printing, and precision casting to quickly produce functional prototypes and small-to-medium production runs.

Partnering with a china rapid prototyper means accessing cutting-edge manufacturing capabilities that significantly shorten the product development cycle, from initial design to functional prototype testing. This agility is vital for businesses aiming to bring innovative products to market faster, respond swiftly to customer feedback, and stay ahead of competitors.

The Advantages of Collaborating with a China Rapid Prototyper

1. Accelerated Product Development Timeline

One of the primary benefits of working with a china rapid prototyper is the dramatic reduction in lead times. Traditional manufacturing processes can take weeks or even months, causing delays that hamper time-to-market. In contrast, China-based rapid prototyping companies employ advanced machinery and streamlined workflows to produce prototypes within days. This rapid turnaround allows businesses to iterate designs quickly based on testing and customer feedback, speeding up overall development cycles.

2. Cost-Effective Manufacturing Solutions

Cost reduction is another compelling reason to engage a china rapid prototyper. India has access to highly skilled labor and lower material costs, enabling the production of high-quality prototypes at a fraction of the cost compared to Western counterparts. Additionally, economies of scale and optimized manufacturing processes ensure that even complex metal parts can be produced affordably, making them perfect for startups, small batch productions, or testing phases.

3. Superior Quality and Precision

Modern china rapid prototyper facilities leverage CNC machining, 3D printing with metal powders, and advanced casting techniques to deliver prototypes with exceptional accuracy. This high level of precision ensures that prototypes closely resemble final production parts, enabling thorough testing and validation before mass manufacturing. Such meticulous quality control reduces errors, minimizes rework, and assures that the product meets stringent industry standards.

4. Flexibility and Customization Capabilities

Chinese rapid prototyping providers are equipped to handle a diverse range of metals, including aluminum, stainless steel, titanium, brass, and more. The flexibility to work with various materials and complex geometries makes them suitable for industries such as aerospace, automotive, medical devices, and consumer electronics. This adaptability ensures businesses can realize innovative designs that might be difficult or costly to produce elsewhere.

5. Enhanced Collaboration and Support

The best china rapid prototyper companies prioritize clear communication, technical support, and collaborative development. They often provide comprehensive services, including design optimization, material selection, and post-processing options such as surface finishing and coating. Engaging a partner that understands your requirements and offers end-to-end support streamlines development and ensures project success.

Key Technologies Utilized by Leading China Rapid Prototyper Facilities

- CNC Machining: Precision cutting of metals with computer-controlled tools, capable of producing complex parts with tight tolerances.

- Metal 3D Printing: Additive manufacturing processes such as Direct Metal Laser Sintering (DMLS) enable the creation of intricate, lightweight, and high-strength metal components.

- Investment Casting: Also known as lost wax casting, ideal for producing detailed and durable metal parts, especially in prototypes with complex geometries.

- Metal Die Casting: Suitable for larger production runs with high precision and surface quality, often used after initial prototyping phases.

- Surface Finishing & Treatment: Techniques like polishing, anodizing, plating, and coating improve the aesthetic and functional qualities of metal prototypes.

How to Choose the Right China Rapid Prototyper Partner for Metal Fabrication

1. Evaluate Technical Capabilities

Ensure the provider has a comprehensive array of manufacturing technologies suitable for your project specifications. Verify their experience with your chosen metals, complex geometries, and finishing options.

2. Review Quality Standards and Certifications

Look for companies adhering to international quality management standards such as ISO 9001, ISO 13485 (for medical devices), or AS9100 (aerospace). Certifications demonstrate a commitment to quality control and reliability.

3. Assess Turnaround Times and Flexibility

Find a partner known for quick delivery, responsiveness, and adaptability to design changes, especially during early development phases.

4. Consider Communication and Support Services

Effective collaboration hinges on clear communication channels, technical advice, and transparency in the manufacturing process.

5. Review Past Projects and Client Feedback

Examine case studies, client testimonials, and portfolio samples to gauge their expertise in metal prototypes relevant to your industry or product type.

Future Trends in Rapid Prototyping and Metal Fabrication in China

The industry is continuously evolving with technological advancements that promise to further improve china rapid prototyper capabilities. Some key trends include:

- Integration of Artificial Intelligence (AI): AI-driven design optimization and process control enhance precision and reduce waste.

- Expansion of Metal 3D Printing: More alloys and larger build volumes expand possibilities for complex prototype designs.

- Sustainable Manufacturing: Focus on eco-friendly materials and processes reduces environmental impact.

- Industry 4.0 Implementation: Smart factories with interconnected machinery enhance efficiency, traceability, and customization.

Why DeepMould.net is Your Ideal Partner in Metal Fabrication

As a premier provider within the industry, deepmould.net embodies all the qualities essential for a successful collaboration with a china rapid prototyper. With a strong focus on metal fabrications, state-of-the-art technology, and dedicated technical support, DeepMould delivers high-precision prototypes tailored to your project needs.

DeepMould.net emphasizes quality control, fast turnaround times, and competitive pricing, ensuring your business maintains a competitive edge. Their extensive experience across various industries, including automotive, aerospace, medical, and industrial equipment, makes them a trusted partner for companies seeking reliable, high-end metal prototypes and small batch production.

Maximize Your Business Potential with a China Rapid Prototyper

In today's cutthroat market, speed, quality, and cost-efficiency are paramount. Incorporating a china rapid prototyper into your product development strategy can unlock new opportunities, enabling your enterprise to:

- Reduce Time-to-Market: Get your products into customers' hands faster than ever before.

- Enhance Design Iterations: Quickly test and refine prototypes to optimize performance and manufacturability.

- Lower Costs: Save on development and tooling costs during early stages.

- Improve Product Quality: Achieve precision and durability in prototypes that closely resemble final production parts.

- Maintain Competitive Edge: Stay ahead through innovation, agility, and responsive manufacturing.

Concluding Remarks: Embrace the Future of Metal Fabrication

The emergence of china rapid prototyper services has revolutionized the way businesses approach product development and manufacturing. For companies targeting high-quality, precise, and cost-effective metal prototypes, partnering with a reliable Chinese provider like deepmould.net offers unmatched advantages. This strategic move ultimately enhances your innovation capacity, accelerates project timelines, and allows you to deliver superior products to your customers.

Remember, in the competitive world of modern business, embracing advanced manufacturing technologies and international partnerships is essential for sustained growth and success. Position your enterprise at the forefront of industry innovation by leveraging the full potential of a top-tier china rapid prototyper.