Essential H2S Awareness Training for a Safer Workplace

In industries where hydrogen sulfide (H2S) is prevalent, such as oil and gas, mining, and sewage treatment, H2S awareness training becomes not just beneficial but essential for ensuring employee safety. This substance, known for its characteristic foul odor resembling rotten eggs, poses serious risks to workers if proper training and protocols are not in place. This article explores the critical aspects of H2S awareness training, the hazards associated with H2S exposure, and the best practices for ensuring workplace safety.

Understanding Hydrogen Sulfide: The Threat Behind the Smell

Hydrogen sulfide is a colorless gas that is extremely toxic and flammable. It can be found in various industrial processes and natural sources, such as:

- Oil and gas drilling

- Natural gas processing

- Sewage treatment plants

- Pulp and paper production

- Mining operations

Exposure to H2S can occur through inhalation or skin contact, and its effects can be devastating. Symptoms of exposure may range from mild irritation to severe health issues, including:

- Nausea

- Headaches

- Respiratory distress

- Loss of consciousness

- Death in extreme cases

It is crucial for every worker in environments where H2S is present to receive unparalleled training and awareness to mitigate these risks efficiently.

The Importance of H2S Awareness Training

H2S awareness training equips employees with the knowledge and skills to recognize, prevent, and respond effectively to H2S-related emergencies. Here are the primary benefits of implementing this training:

- Increased Safety: Understanding the dangers of H2S and learning how to use personal protective equipment (PPE) properly can save lives.

- Regulatory Compliance: Many jurisdictions require H2S training as part of health and safety regulations. Compliance can help avoid legal issues and fines.

- Improved Emergency Response: Preparedness through training ensures that employees can act swiftly and effectively during H2S exposure incidents.

- Enhanced Workplace Culture: Prioritizing safety through comprehensive training instills a culture of vigilance and care among all staff members.

Components of Effective H2S Awareness Training

An effective H2S awareness training program should encompass various components to ensure comprehensive understanding and preparedness. Key elements include:

1. Recognition of H2S Hazards

Employees should be trained to identify environments where H2S is likely to be present. This includes understanding operational procedures, recognizing the signs of leaks, and being aware of areas considered H2S “hot spots.”

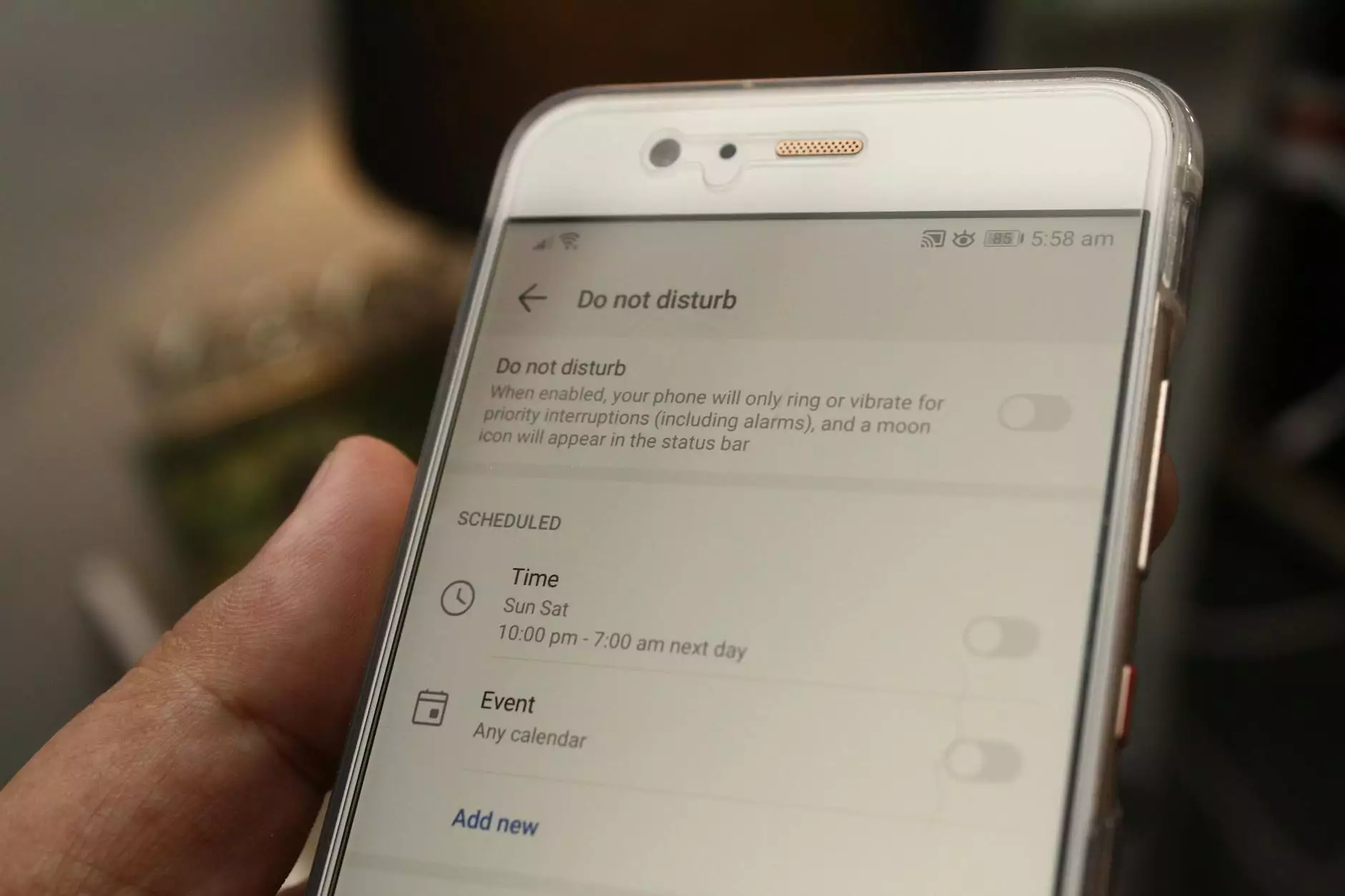

2. Monitoring Techniques

Training should cover the use and maintenance of H2S detection devices, such as portable gas monitors and fixed gas detection systems. Knowing how to interpret readings from these devices is crucial for ongoing safety.

3. Personal Protective Equipment (PPE)

Proper use of PPE, including gas masks and protective clothing, plays a significant role in safeguarding workers. Training should guide workers on choosing appropriate PPE based on specific exposure levels and how to inspect and maintain their equipment.

4. Emergency Response Procedures

In the event of an H2S exposure incident, quick and appropriate action can save lives. Training must include:

- Evacuation routes and procedures

- First aid measures for H2S exposure

- Reporting protocols to notify supervisors and safety officers

Regulatory Standards and Compliance

Regulatory agencies such as OSHA (Occupational Safety and Health Administration) set strict guidelines regarding H2S exposure in the workplace. Compliance with these standards is non-negotiable for employers. In the U.S., OSHA's H2S Standard articulates the necessary precautions and training required for workers exposed to H2S environments.

Employers must ensure that:

- Employees undergo regular H2S awareness training.

- Appropriate signage is displayed in potential H2S exposure areas.

- Regular safety drills and emergency preparedness sessions are conducted.

- PPE is available and correctly fitted for all employees.

Best Practices for Implementing H2S Awareness Training

To maximize the effectiveness of H2S awareness training within your organization, consider the following best practices:

1. Regular Training Updates

H2S risks can change due to operational modifications or new equipment. Scheduling regular training sessions helps keep the workforce updated on the latest safety practices.

2. Engage Qualified Trainers

Utilizing experienced and certified trainers ensures that all content is accurate, relevant, and in line with current regulations and technological advancements.

3. Utilize Interactive Learning Techniques

Incorporate hands-on training, simulations, and scenario-based exercises to create highly engaging training experiences that enhance knowledge retention.

4. Assess Training Effectiveness

Conduct assessments following training sessions to evaluate the workers' understanding and effectiveness of the training program. This can include quizzes, practical assessments, or feedback surveys.

Conclusion: Prioritizing Safety Through H2S Awareness Training

In high-risk industries, H2S awareness training is not merely a regulatory requirement but a critical component of workplace safety. By investing time and resources into comprehensive training, employers can significantly reduce the risks associated with hydrogen sulfide exposure.

At h2sonlinetraining.com, we provide tailored H2S awareness training programs that address the specific needs of your workforce. Ensure your team is prepared and equipped for any situation involving H2S; their safety depends on it. Together, let’s advance towards a safer work environment where every employee is empowered with the knowledge and skills to thrive.

For more information on H2S awareness training, please visit our website at h2sonlinetraining.com.