Understanding the Role of Car Parts Manufacturers in the Automotive Industry

The automotive industry thrives on the seamless integration of various components, and at its core, the car parts manufacturers play a pivotal role. These manufacturers are the unsung heroes of the industry, supplying essential components that ensure vehicles operate efficiently and safely.

The Importance of Car Parts Manufacturers

Car parts manufacturers serve as the backbone of the automotive sector. Their influence is widespread, impacting everything from vehicle performance to safety standards. With the rise in demand for vehicles globally, the need for specialized manufacturing processes and high-quality components has never been greater.

Quality and Safety Standards

Quality control is a fundamental aspect of operations in this sector. Car parts manufacturers are obligated to adhere to stringent regulatory standards, ensuring that every component meets the necessary safety requirements. This not only helps in protecting consumers but also builds trust and reliability in the brands they support. Below are some key quality assurance practices:

- Material Selection: Utilizing high-grade materials to ensure durability.

- Testing Protocols: Conducting rigorous tests to ascertain performance under various conditions.

- Certification: Obtaining credentials from relevant authorities to validate their standards.

Innovation in Car Parts Manufacturing

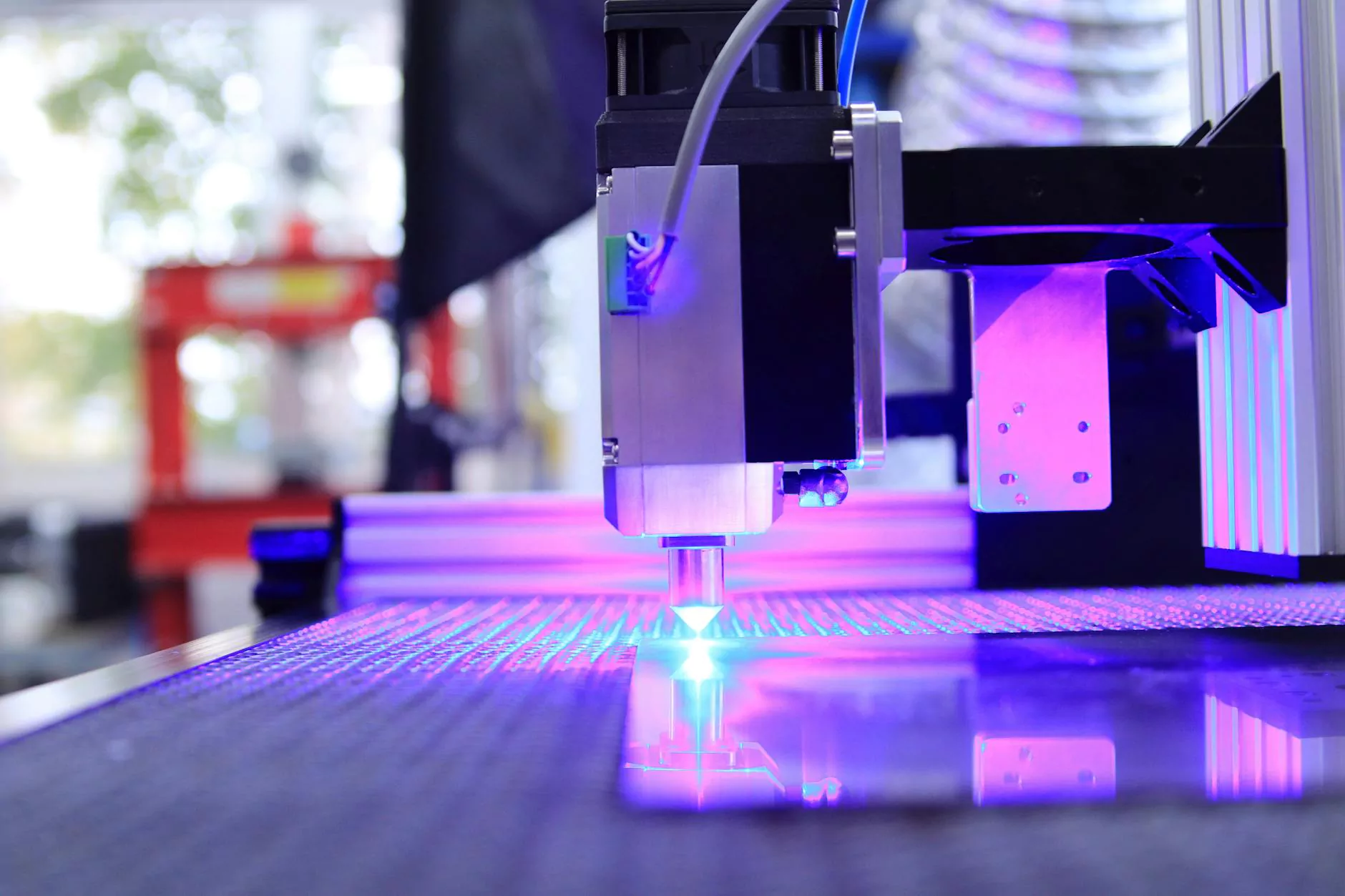

Innovation is at the heart of the automotive industry, and car parts manufacturers are continually pushing the boundaries to enhance vehicle capabilities. Modern manufacturing techniques leverage advanced technology, enabling these manufacturers to produce parts that are not only more efficient but also cost-effective.

Technological Advancements

With the advent of new technologies, the landscape of car parts manufacturing has transformed dramatically. Innovations such as 3D printing, robotics, and automation have allowed manufacturers to produce complex components with precision. The benefits include:

- Reduced Production Time: Speeding up the manufacturing process and shortening lead times.

- Cost Efficiency: Lowering production costs with automated processes.

- Customization: Offering tailored components that meet specific customer needs.

Global Supply Chain Dynamics

The global supply chain for car parts manufacturing is intricate and vast. Manufacturers often source materials from various regions to ensure that they maintain the highest quality at competitive prices. This interconnectedness also highlights the strategic importance of logistics and distribution networks.

Challenges in the Supply Chain

Despite its advantages, the global supply chain faces several challenges, including:

- Trade Regulations: Tariffs and regulations can impact sourcing strategies and costs.

- Logistical Issues: Transportation delays can disrupt the timely delivery of components.

- Operational Risks: Factors such as natural disasters or geopolitical tensions can impede operations.

Environmental Considerations in Car Parts Manufacturing

As the automotive industry shifts towards sustainability, car parts manufacturers are increasingly focusing on minimizing their environmental footprint. This includes adopting eco-friendly practices throughout the production process.

Sustainable Manufacturing Practices

To address environmental concerns, many manufacturers implement sustainable practices such as:

- Recycling Materials: Utilizing recycled materials in production to reduce waste.

- Energy Efficiency: Incorporating energy-saving technologies in manufacturing processes.

- Reduction of Emissions: Implementing strategies to lower greenhouse gas emissions from production facilities.

Future Trends for Car Parts Manufacturers

The future of car parts manufacturing is exciting and rife with potential. With the rise of electric vehicles (EVs), manufacturers must adapt to new standards and consumer demands. Additionally, the integration of artificial intelligence and IoT (Internet of Things) will further revolutionize manufacturing processes and vehicle performance.

Electric and Autonomous Vehicle Components

The surge in electric and autonomous vehicle production creates a fresh array of opportunities for car parts manufacturers. Specialized components for EVs, such as batteries and electric drivetrains, require unique manufacturing techniques. Furthermore, as vehicles become increasingly autonomous, manufacturers will need to focus on:

- Sensor Manufacturing: Developing precise sensors for vehicle navigation and safety.

- Software Integration: Collaborating with software developers to create intelligent systems.

Conclusion: The Future of Car Parts Manufacturers

In conclusion, car parts manufacturers are essential to the health and progress of the automotive industry. As the sector faces evolving challenges and opportunities, these manufacturers must stay abreast of technological advancements, environmental sustainability, and market trends. By doing so, they will not only meet consumer demand but also help shape the future of transportation.

Discover Quality Auto Parts at imautoparts.com

For those in search of quality automobile components, imautoparts.com provides a vast range of products that meet the high standards expected by today’s consumers. From engine parts to replacement supplies, finding quality auto parts has never been easier. Explore their offerings and experience firsthand the difference quality components make in vehicle performance.